Mistral Grain Drier

Grain drying is a Perry speciality, and enormous expertise has developed the company into a leader in this field. Perry are world-renowned for manufacturing continuous flow grain driers and have been successfully doing so since 1955. This range of grain driers is available with capacities from 5tph to 30tph and is suitable for a wide range of cereal crops including wheat, barley, oats and maize, Perry continuous flow grain driers are now in use in many countries across the world.

The Mistral Series Continuous Mixed Flow Drier is a cost effective solution, designed to be an entry level static drier for farmers looking to dry up to 30tph of combinable crops.

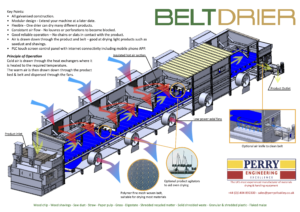

Principle of Operation

Grain is elevated to the top of the drier column and enters the drier tower through the reserve section. When in full operation the entire drying column is filled with grain; discharge of dried grain occurs via a roller discharge to provide a constant flow of grain. This results in grain gradually working its way down the drying column, firstly in contact with hot air, then cooling air for the last 25-30% of the column. The discharged grain is then both of the correct moisture content and temperature for long term storage.

The design of the drier is such that the grain column is completely ledge free reducing dust and chaff residue. The tapered design of the air ducts promote even airflow and ensure uniform drying across the whole grain column.

As standard, the Mistral drier is controlled via a hard-wired control panel, though this is easily upgradable to the Perry PLC Touch Screen Control Panel. Control can be further enhanced by specifying the dynamic moisture control system, which is an optional extra on all Perry continuous flow driers, or can be retro-fitted to an existing drier.

Key Points

- Designed with the same efficiencies and expertise as the Savannah Series Grain Driers.

- Burner and fuel options – diesel, kerosene, gas steam, coal using heat exchangers or biomass heat sources as options (direct or indirect fired).

- Highly efficient axial flow fans – Optional inverter-controlled fans for ease of control when drying light crops and for energy saving.

- Discharge – the Mistral range of grain driers are fitted with Perry’s proven roller discharge.

- CentriKleen – the cost-effective, simple solution to dust and chaff problems, which can be fitted to existing axial fans on all makes of driers.

- Fire detection – can help provide early warning of a fire, helping to reduce potential damage to the drier. It is for use to detect fire within a grain drier drying column.

- Commissioning and support – all Perry driers are commissioned by in-house experienced engineers, who provide expert technical advice and future servicing for complete satisfaction. There is also a dedicated technical support line to provide the first point of call for all technical enquiries on any Perry machine.

- Capacities and sizes available

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

WHY DO SO MANY IN THE FARMING COMMUNITY BUY FROM PERRY OF OAKLEY?

The machines last The Perry machines are built to last and we have our records going back well into the 1960s so if a machine needs a replacement part, we know exactly what it needs and we can get it manufactured and out to you quickly. We are so confident in the...

SEASONS GREETINGS FROM PERRY OF OAKLEY LTD.

Wishing you a fantastic festive period, and a Happy New Year, from all at Perry! Our factory will close at 5pm on Wednesday 22nd December 2021 and will reopen at 8am Tuesday 4th January 2021. If you need us urgently during the break please email...