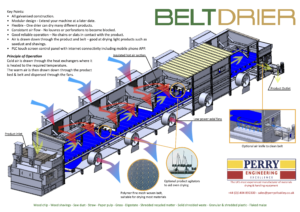

Hot Air Recirculation

Significantly reduce your grain drier fuel costs by using Hot Air Recirculation

Save up to 24%* of your grain drier fuel costs

How Does It Work?

The grain drier fuel savings come from the reduction in the amount of fuel the drier consumes to heat the air to dry the grain.

The cooling air, from the lower levels of the grain drier, which is unsaturated and of the highest temperature, is recirculated to the hot air side of the drier and remixed with the heated air.

Depending on the drier size, 25% to 30% of the warmest air in the drier is moved by the recirculation fan along transfer ducts to an additional plenum and mixed with the freshly heated ambient air.

*The actual percentage savings on drier operating costs by using Hot Air Recirculation can be significant and will vary based on:

- Hot air and ambient air temperature

- Crop type and moisture

- Drier model & fan speed

- Ambient conditions

Some examples of the theoretical level of grain drier fuel cost savings are:

125°C hot air temperature, 15°C ambient, percentage saving 16% to 18% depending on drier model selected.

70°C hot air temperature, 15°C ambient, percentage saving 21% to 24% depending on drier model selected.

Maximise Your Operational Savings

Increase your theoretical operational cost savings up to 35% by combining Hot Air Recirculation with:

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

WHY DO SO MANY IN THE FARMING COMMUNITY BUY FROM PERRY OF OAKLEY?

The machines last The Perry machines are built to last and we have our records going back well into the 1960s so if a machine needs a replacement part, we know exactly what it needs and we can get it manufactured and out to you quickly. We are so confident in the...

SEASONS GREETINGS FROM PERRY OF OAKLEY LTD.

Wishing you a fantastic festive period, and a Happy New Year, from all at Perry! Our factory will close at 5pm on Wednesday 22nd December 2021 and will reopen at 8am Tuesday 4th January 2021. If you need us urgently during the break please email...