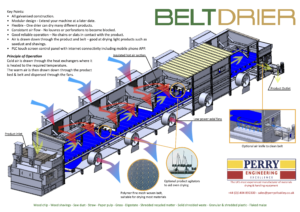

PLC Drier Control Panel

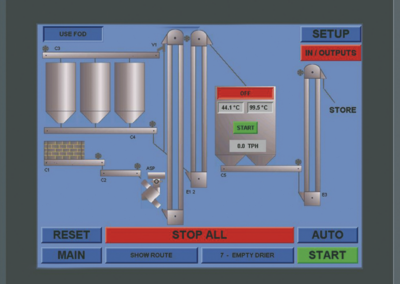

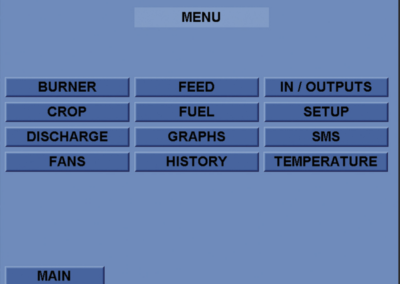

The Perry PLC Drier Control Panel is an advanced piece of technology that gives the drier operator a clear, visual representation of the drier along with offering advanced diagnostic capabilities & remote control, when the panel is connected to the internet.

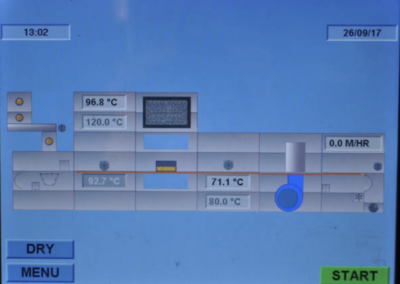

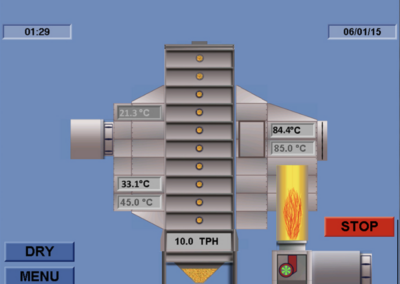

The Perry PLC Drier Control Panel comes as standard with both the Perry Savannah Series Continuous Mix Flow Driers & the Perry Belt Drier. The difference between the two panels being the visual representation of the drier & products available in the crop set-up pages.

The PLC Drier Control Panel can be upgraded to become a full PLC Plant Control Panel , which will allow the control panel to control your entire plant, including machines by other manufacturers.

Key Points

- 12” touch screen.

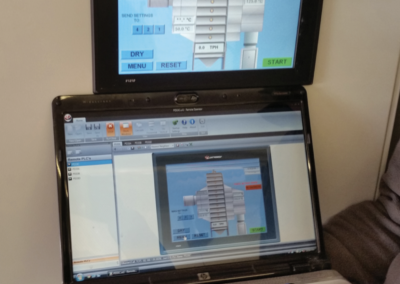

- Internet connectivity* allows for remote operation via an app or PC.

- Simple operation.

- Over 70 alarms and messages.

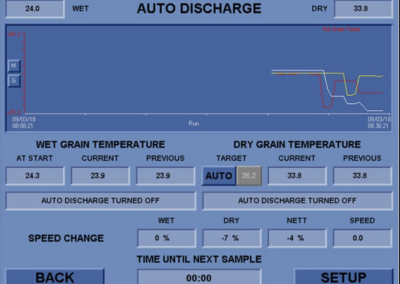

- Automatic moisture control system. This uses temperatures at the top and bottom of the drier to monitor incoming and outgoing moisture changes and control the drier discharge speed accordingly.

- Plain language status alerts.

- Designed and programmed in house, by our own experienced engineers.

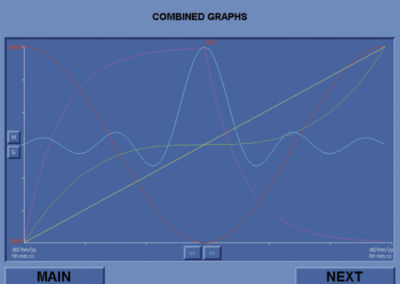

- Data logging of all readouts and alarms & drier status.

- Recirculating batch mode included for continuous flow driers – requires an additional empty probe.

Internet Connectivity

Advances in technology are allowing farmers to save both time and money by becoming more mobile and less reliant on traditional, labour-intensive farming methods. A key factor a Perry is being up to date with technological advances, along with wanting to provide customers with a quality product. A mobile phone application is also available that allows control of the Perry Drier or Plant Control Panel.

- Control a drier from either a PC or an app (available in the Google Play Store or Apple App Store).

- Export all recorded drier conditions and moisture contents to a spreadsheet and automatically create daily record sheets.

- Allow status reports to be sent to selected mobile numbers and email addresses.

- Download all drier history and data logged records.

- Allow UK engineers to access the panel for diagnostics or adjustments while you watch the screen.

*Requires internet connection and modem for all features.

Automatic Grain Moisture Control System

The Perry drier auto discharge control system included within the panel operates using a list of user-adjustable parameters to enable each drier to be tuned to the customer’s needs. These include the sensitivity, rate of sampling and target hot grain temperatures. The system uses the wet grain and dry grain temperature either individually or as a combination of the two to control the speed of the drier and to maintain the grain moisture content. This makes it one of the leading methods of control on the market today.

* Panel must be connected to the internet with a static IP address and port forwarding facility, no app currently available for Windows devices.

Diagnostics

The drier history is recorded – input and output screens display current panel conditions to aid fault diagnostics. When the Perry drier is connected to the internet, diagnostics and status reports can be sent directly to a smart phone via email or text message.

Everything You Should Know About Grain Sentry Fire Detection

When correctly positioned and functioning, the Perry Fire Detection System can help provide early warning of a fire, helping to reduce potential damage to your drier. It’s used for detecting fire within a grain drier drying column. Belt Drier Fire Detection...

Which Type of Grain Drier Should I Buy?

With over 70 years of experience, Perry Engineering are the UK’s most experienced manufacturer of materials drying and handling equipment. Our driers are relied on to dry a variety of crops in different climates all over the world. How do you know which type of grain...

Why Buy a Perry Mistral Grain Drier?

Investing in the Mistral Grain Drier Grain drying is a Perry of Oakley speciality, and our extensive expertise has established us as a leader in this field. At Perry we’re world-renowned for manufacturing continuous-flow grain driers. We’ve been successfully...