Silo Auger Discharge System

Perry’s Silo Auger Discharge System is purposefully designed to unload round flat bottom silos quickly and efficiently. With capacities available from 40tph to 240tph as standard, the Silo Auger Discharge System is ideally suited to commercial grain stores, as well as smaller farms.

Due to the unique nature of this product, each one is made to order to suit the individual needs of our customers meaning the customer gets an end product tailored to their needs.

Our system allows for maximum emptying efficiency as it’s designed with one main inlet in the centre of the silo then multiple intermediate inlets spread from the centre of the silo out towards the edge. Each inlet has individual rack and pinion control, allowing for full and individual control of each inlet.

This purpose built system allows you to empty your silo quickly, easily and safely, in turn saving you both time and money.

All of Perry’s machinery is designed and manufactured in a purpose built manufacturing facility in the South West of England.

Key Points

- 200, 250 & 300mm diameter agricultural & industrial specification available.

- 40tph to 240tph as standard other capacities priced on application.

- 3mm or 5mm thick casing tube.

- Gear unit or V belt drive options available.

- Each one made to order, to suit customer requirements.

- Individual rack and pinion control of inlet slides.

- Two layers of bitumastic paint making them suitable for casting in concrete.

- External section in hot dip galvanised finish.

- Continuously welded flights in 2m long sections for easy removal.

- Blockage probe at discharge end.

- Conduit for sweep auger power cable, support legs and lifting lugs all welded in position.

- Pivot bracket for sweep auger.

- Stainless steel slides and operating rods to aid long term reliability.

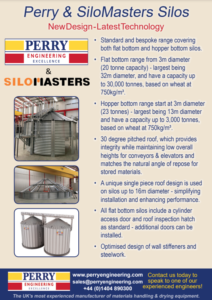

In addition to the standard silo range, within the scope of supply will be:

- Complete aeration systems (fans, perforated floors, etc.).

- Temperature control systems (portable or with computers).

- Unloading equipment.

- Walkways & catwalks – the catwalk system is modular to be able to adapt to all types of conveyor loads and to any design of the plant.

- Towers and structures (supporting columns, work towers, structures for loading silos of trucks / trains).

*All photo’s are from previous Perry of Oakley Ltd installations.

PERRY DURING COVID-19

Managing Director, David Perry, said “It is imperative that our British farmers are able to continue to support this country through these uncertain times, as a company we aim to support them every way we can with the help of our trusted dealer network. From new...

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

WHY DO SO MANY IN THE FARMING COMMUNITY BUY FROM PERRY OF OAKLEY?

The machines last The Perry machines are built to last and we have our records going back well into the 1960s so if a machine needs a replacement part, we know exactly what it needs and we can get it manufactured and out to you quickly. We are so confident in the...