Flat Bottom Silos

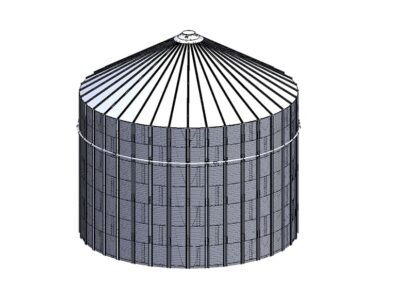

Perry’s have introduced an extensive range of flat bottomed silos which carry the Perry & Silomasters brand. Designed by a team of specialists with over 50 years of global silo experience the silos are manufactured on state of the art equipment and can be specified to meet either ANSI or Eurocode standards depending on the destination country.

Key Points

- All galvanised construction manufactured from S350 and S450 steel and galvanised to Z600 standard for a long life.

- Round flat bottom silo capacities from 30 to 20,000 tonnes based on wheat at 750kg/m³.

- Galvanised, stainless, mild steel & painted options.

- Modular design.

- Standard flat bottom silos range from 3m diameter (30 tonnes storage) to 32m diameter (20,000 tonnes storage).

- Custom diameters available to suit existing bases if replacing an end of life silo.

- All silos are designed for high cyclic loading – high usage of product in and out at high tonnage rates.

- Special silos available to suit customer’s applications – standard and bespoke range.

- 30 degree pitched roof, which provides integrity while maintaining low overall heights for conveyors & elevators and matches the natural angle of repose for stored materials.

- A unique single piece roof design is used on silos up to 16m diameter – simplifying installation and enhancing performance.

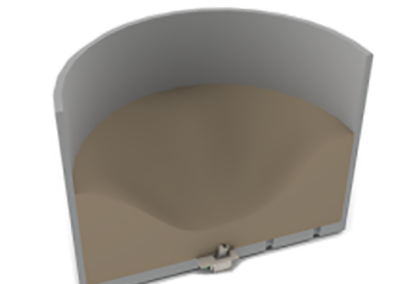

- All flat bottom silos include a cylinder access door and roof inspection hatch as standard – additional doors can be installed.

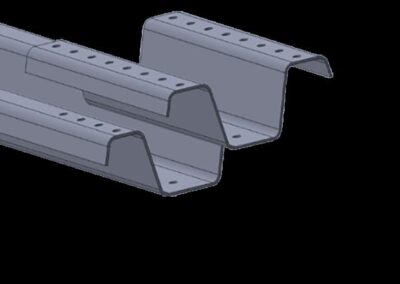

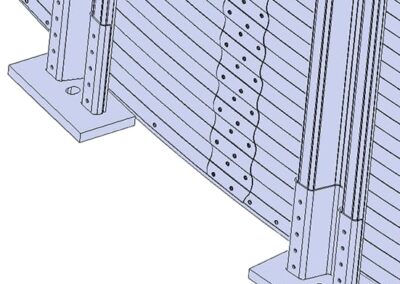

- Optimised design of wall stiffeners and steelwork.

- Silos have a smooth-wall construction and are also perfect for poor-flowing products such as meals and woodchip

Accessories

In addition to the silo range there are also a number of related accessories including:

- Complete aeration systems (fans, perforated floors, etc.)

- Monitoring systems (portable or with computers) for grain moisture, temperature & CO2.

- Unloading equipment (sweepers, augers).

- Walkways & catwalks – the catwalk system is modular to be able to adapt to all types of conveyor loads and to any design of the plant. Standard catwalk widths between 1m and 3.6m, including a 1.1m double handrail. Custom sizes are available on request.

- Towers and structures (supporting columns, work towers, structures for loading silos of trucks / trains)

Go to Silo Accessories for more information

*All photos are from previous Perry of Oakley Ltd installations.

Everything You Should Know About Grain Sentry Fire Detection

When correctly positioned and functioning, the Perry Fire Detection System can help provide early warning of a fire, helping to reduce potential damage to your drier. It’s used for detecting fire within a grain drier drying column. Belt Drier Fire Detection...

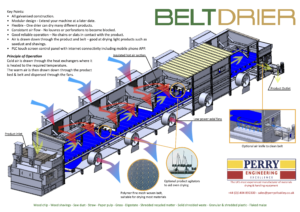

Which Type of Grain Drier Should I Buy?

With over 70 years of experience, Perry Engineering are the UK’s most experienced manufacturer of materials drying and handling equipment. Our driers are relied on to dry a variety of crops in different climates all over the world. How do you know which type of grain...

Why Buy a Perry Mistral Grain Drier?

Investing in the Mistral Grain Drier Grain drying is a Perry of Oakley speciality, and our extensive expertise has established us as a leader in this field. At Perry we’re world-renowned for manufacturing continuous-flow grain driers. We’ve been successfully...