Silo Accessories

As part of the Perry Silo range we can also supply:

- Complete aeration systems (fans, perforated floors etc.)

- Temperature control systems (portable or with computers).

- Walkways and catwalks

- Towers and structures (supporting columns, work towers, support structures for truck / train loading silos).

Catwalks

The standard catwalk feature has widths ranging from 1m to 3.6m. These consist of a double handrail with a vertical height of 1.1m and a half-height safety rail supported every 1.5m by vertical handrail posts, and a kickboard. The catwalk’s standard full width floor is constructed from galvanised grating sheets of 30 x 30mm.

A pre-punched floor and part flooring can also be provided. The catwalk’s construction is made of galvanised profiled beams. The design includes three beams to accommodate heavier conveyor loads. This also lowers the chance of deck sag. To help avoid trip risks, the decking is installed directly on top of the beams using dome-headed bolts.

The catwalk system is modular to be able to adapt to all types of conveyor loads and to any plant design.

Aeration

You can choose from flush floor (lateral) systems or full floor aeration systems for flat bottom silos and in-cone aeration systems for hopper silos. For safe storage of grain, we use airflows of 5 to 10m³/hr/ton depending on the product stored and storage duration.

Each system is custom designed to ensure air distributes evenly while reducing the air velocity. The flush floor system uses 530mm wide perforated laterals, and the number per linear metre changes in accordance with the grain loads imposed.

We know that different products and silo heights result in different static pressures. The site elevation is a key factor in selecting the correct fan, as height above sea level increases, the air density decreases affecting the fan airflow. We use state-of-art software to calculate the static pressure and ensure the fan selected meets both variables. We also offer complete in-silo drying systems, roof fans, and associated equipment for your convenience.

The Perry range of centrifugal aeration fans are designed and manufactured in-house. The range starts with a 0.55kW motor fan up to 7.5kW motor operating at either high speed or low speed, which gives us the ability to produce and supply the correct fan for every application. The backward-curved impeller is encased in a fully galvanised housing. Each fan is produced with a large air inlet with safety guard, weather hoods on the air inlet, galvanised transitions and flex couplings are all available as options.

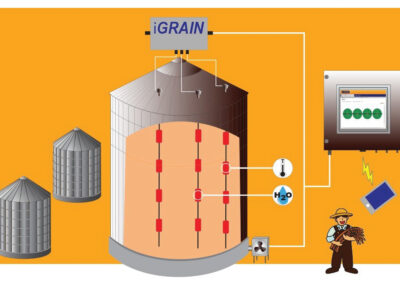

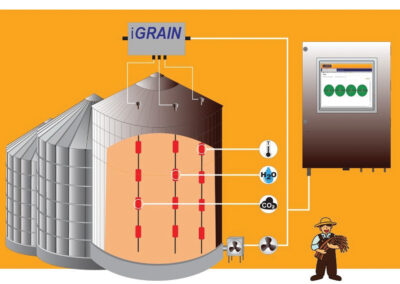

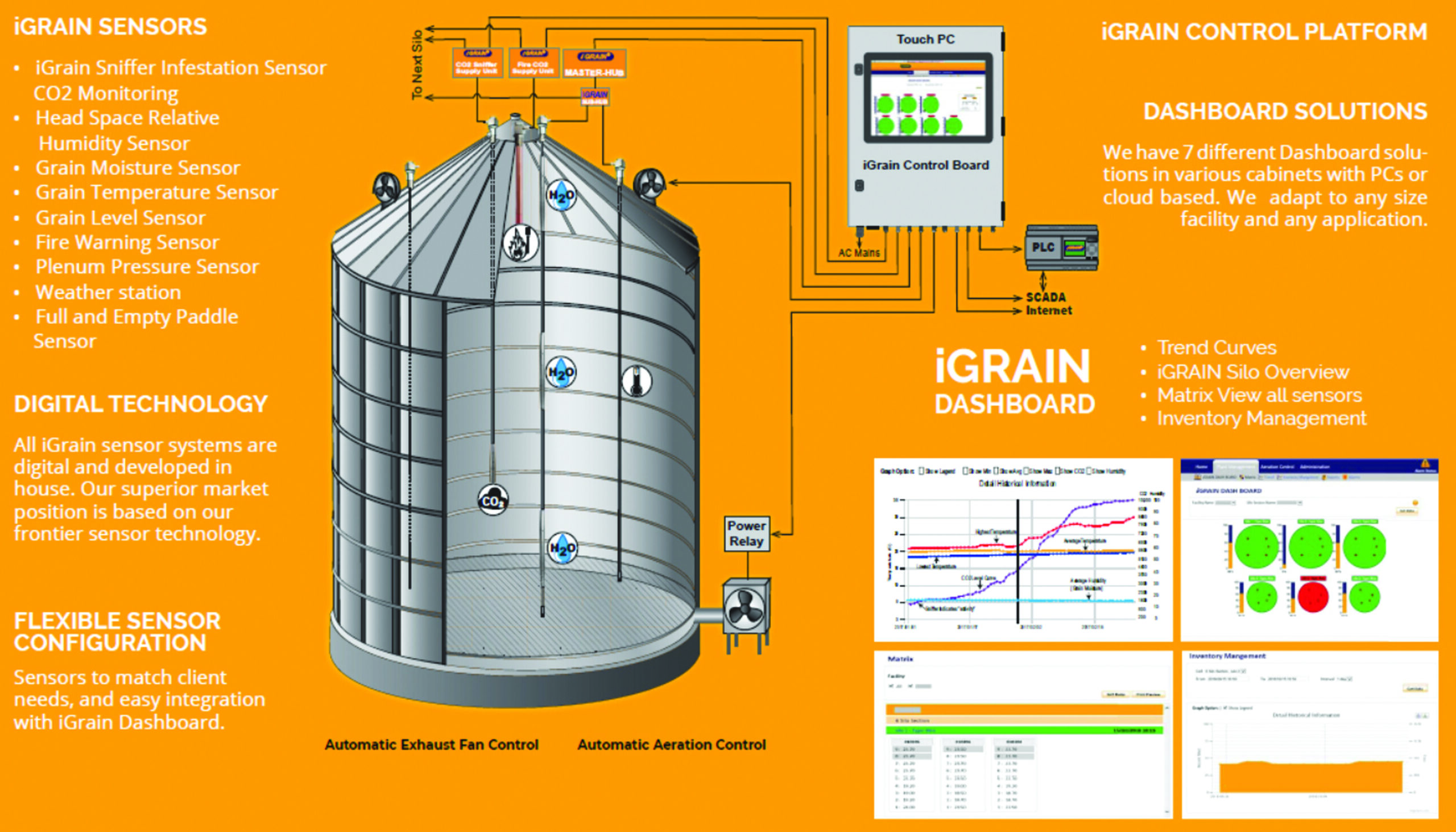

Monitoring Stored Grain

Perry supply the iGrain range of products, which include a handheld reader system and advanced system monitoring grain moisture, temperature and CO2 production in silos and floor stores. The mission is to preserve and optimise crop value and prevent spoilage and fungus.

The iGrain Hand-Held Reader is an efficient tool to display the data collected from the temperature cables.

The CO2 grain sniffer is one of the most advanced methods for effectively identifying an issue with stored grain. The capacity to detect a possible problem within a silo rapidly helps the operator to act more swiftly, decreasing the risk of spoilage.

The Dashboard grain management system automates fan system control and grain care. When a set of predefined criteria are satisfied, the automated aeration control will activate the fans. This allows the fans to be run more efficiently, ensuring grain quality and lowering operational costs.

iGrain systems can be tailored to suit the needs of small-scale farmers as well as large-scale industrial storages of grain, beans, cocoa and coffee, as well as flour, feed and oil mills.

The core iGrain products monitor:

- CO2 for most efficient infestation detection.

- Moisture level.

- Temperature.

Contact us today to discuss your Silo Accessories requirements

Contact us or email [email protected]

Everything You Should Know About Grain Sentry Fire Detection

When correctly positioned and functioning, the Perry Fire Detection System can help provide early warning of a fire, helping to reduce potential damage to your drier. It’s used for detecting fire within a grain drier drying column. Belt Drier Fire Detection...

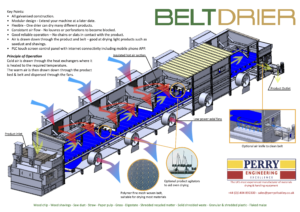

Which Type of Grain Drier Should I Buy?

With over 70 years of experience, Perry Engineering are the UK’s most experienced manufacturer of materials drying and handling equipment. Our driers are relied on to dry a variety of crops in different climates all over the world. How do you know which type of grain...

Why Buy a Perry Mistral Grain Drier?

Investing in the Mistral Grain Drier Grain drying is a Perry of Oakley speciality, and our extensive expertise has established us as a leader in this field. At Perry we’re world-renowned for manufacturing continuous-flow grain driers. We’ve been successfully...