Rotary Cleaners

Rotary cleaners improve grain / cereal quality by removing light dust, chaff & heavier impurities before drying. Cleaning grain / cereal before it is dried is an essential process for grain that is going to be stored for long periods of time. By improving the quality of the grain before it is dried the risk of the grain overheating whilst in storage is reduced. Drier running costs are also reduced as only the best quality grain remains. The amount of dust released into the air whilst being dried is also minimalised.

The aspirator removes light dust and particles, whilst the rotary drum cleaner removes heavier impurities such as chaff, husk and split grains. Capacities begin at 20tph. The main function of a cleaner with aspiration is to remove light dust particles as the product enters the system and then separate the good quality product from the damaged through the rotary drum.

Perrys are distributors for the Musiteli Range of Rotary Cleaners.

The photo is of David Perry the MD of Perrys with Fabrice Debout the MD of Musitelli.

Operation

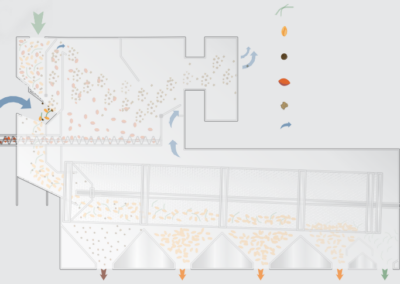

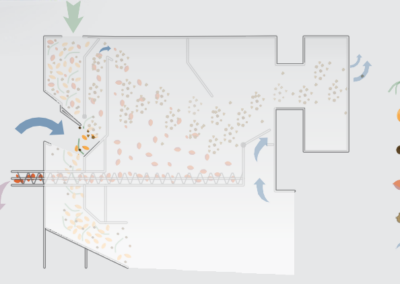

The product is gravity fed into a motorized roller distributor where it is distributed evenly over the entire width of the roller; the subsequent curtain of product is hit by a cross air flow as it descends, which removes the lightest impurities, and deposits part of the heavier impurities in the decantation hopper which is equipped with an auger for reject expulsion.

The dust free product enters a cylindrical rotating drum, covered with interchangeable perforated screens. The first screen removes smaller impurities (sand, split product, etc.).

The dust free product enters a cylindrical rotating drum, covered with interchangeable perforated screens. The first screen removes smaller impurities (sand, split product, etc.). The following screens allow the product to fall through predetermined perforations while any larger impurities are taken to the end of the drum. The type of screens installed are determined by the type of product and the kind of reject material to be separated.

Key points

- Cleaning precision on all types of crops.

- Versatility – from pre-cleaning to grading.

- Vibration free.

- The screen sizes are interchangeable with Marot (Satim), Denis etc.

- Secondary aspiration directly from the cleaning drum.

- Fan has a direct drive.

- Heavy waste dust discharge is positioned at the front of the machine, and can be either side of the good grain inlet.

- The grain inlet has a true bypass valve.

- Main drum inspection doors are manufactured in aluminium (lighter) and open a lot higher for screen access.

- Drum inclination standard on all machines and screw jack adjustment.

- Exclusive variable drum adjustment.

- Secure screen latch for locking screens for removal.

- Robust drum skeleton with keyway shaft.

- Large air mixing chamber for light or heavy chaff / dust.

- Option of being pre-wired.

- Option of single and double hoppers.

- Inverter for drum speed control included.

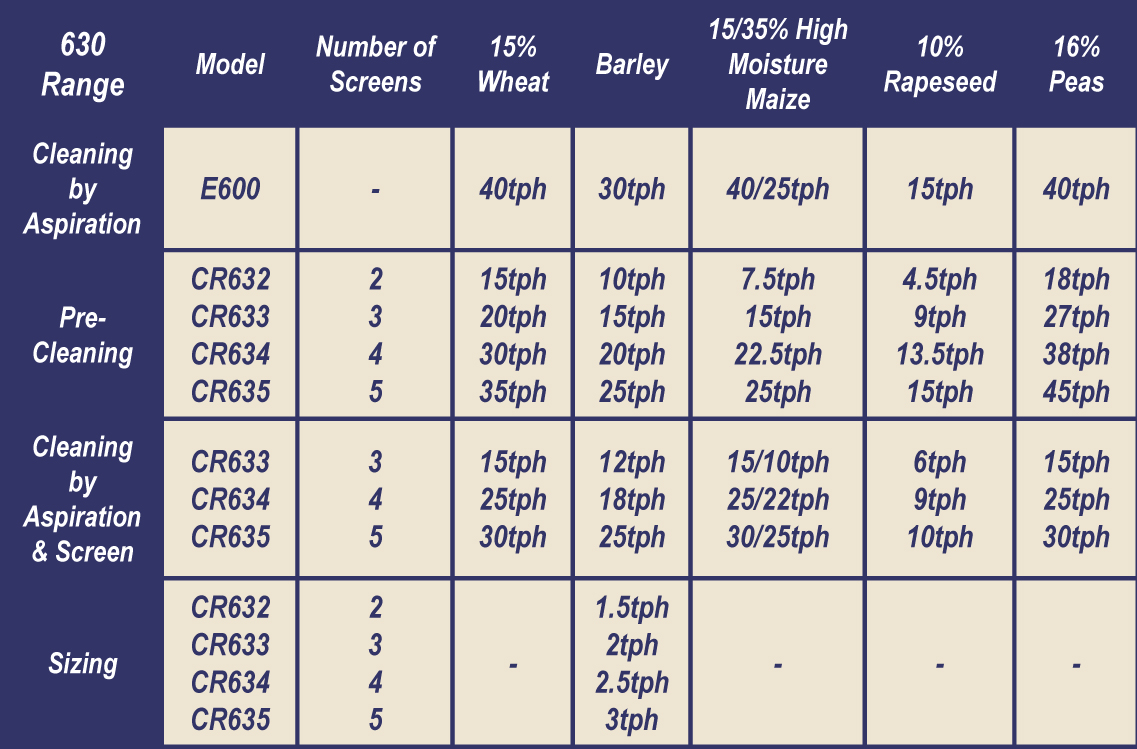

Capacity for the 630 Range

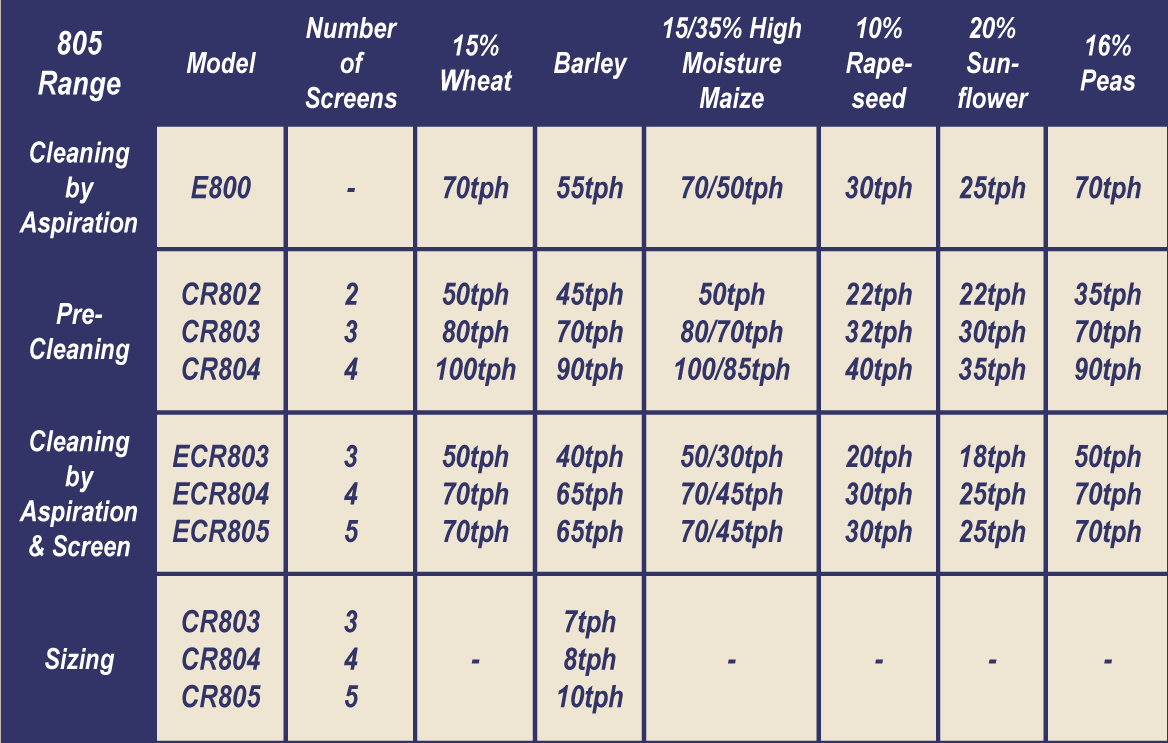

Capacity for the 805 Range

Capacity for the 950 Range

Capacity for the 1260 Range

Dimensions & Power for the 630 Range

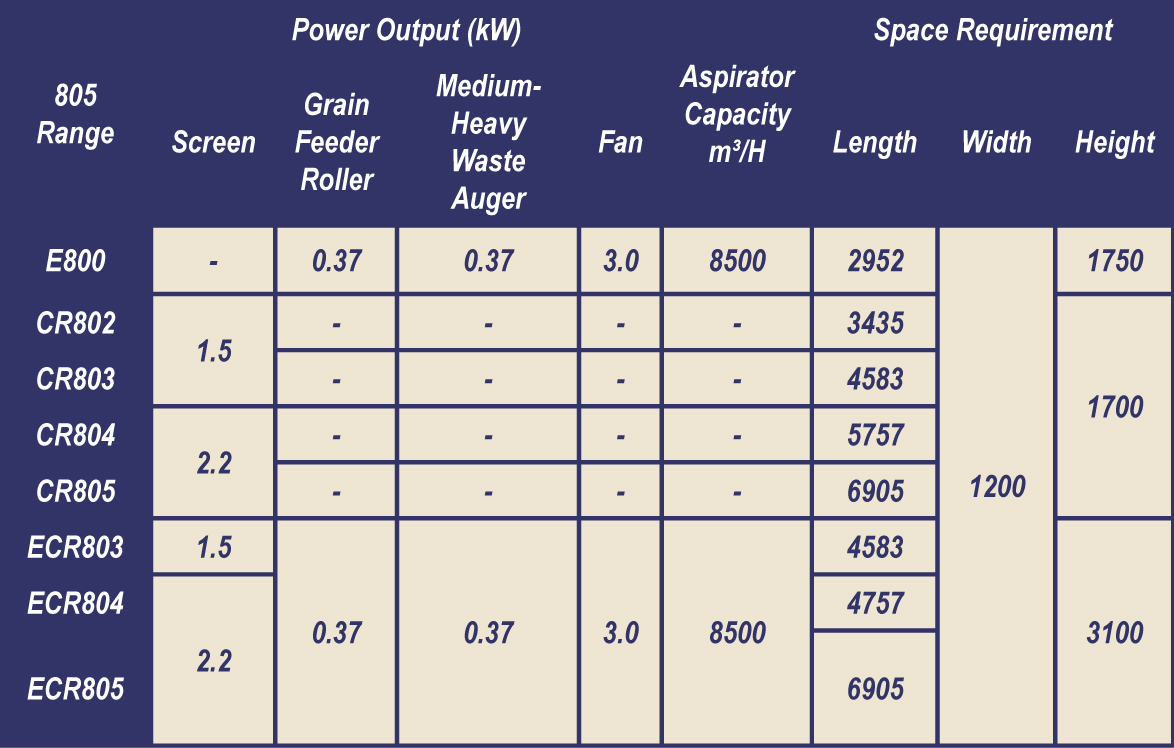

Dimensions & Power for the 805 Range

Dimensions & Power for the 950 Range

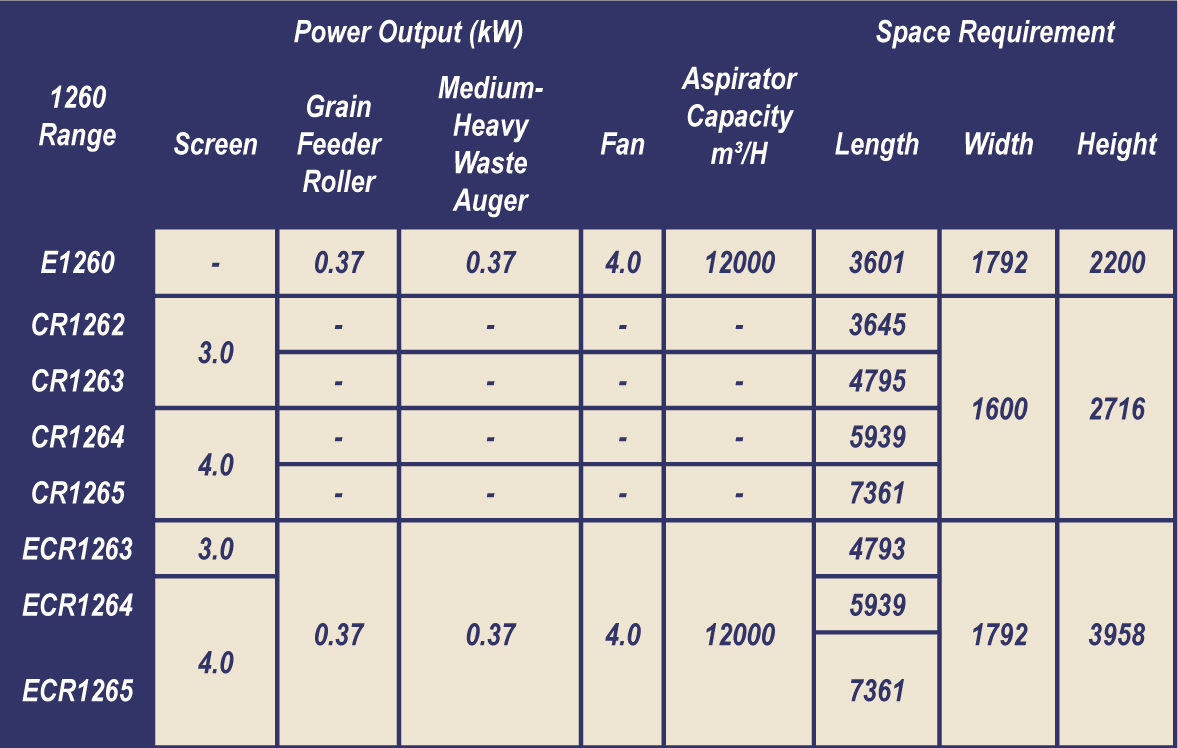

Dimensions & Power for the 1260 Range

Everything You Should Know About Grain Sentry Fire Detection

When correctly positioned and functioning, the Perry Fire Detection System can help provide early warning of a fire, helping to reduce potential damage to your drier. It’s used for detecting fire within a grain drier drying column. Belt Drier Fire Detection...

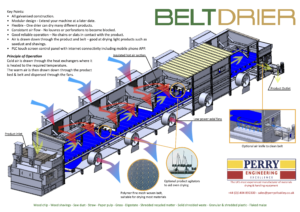

Which Type of Grain Drier Should I Buy?

With over 70 years of experience, Perry Engineering are the UK’s most experienced manufacturer of materials drying and handling equipment. Our driers are relied on to dry a variety of crops in different climates all over the world. How do you know which type of grain...

Why Buy a Perry Mistral Grain Drier?

Investing in the Mistral Grain Drier Grain drying is a Perry of Oakley speciality, and our extensive expertise has established us as a leader in this field. At Perry we’re world-renowned for manufacturing continuous-flow grain driers. We’ve been successfully...