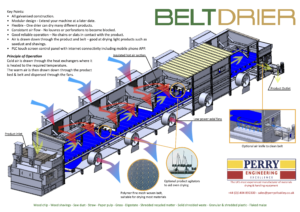

PLC Plant Control Panel

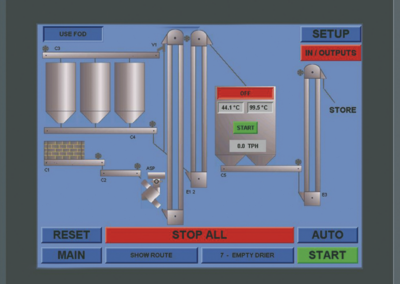

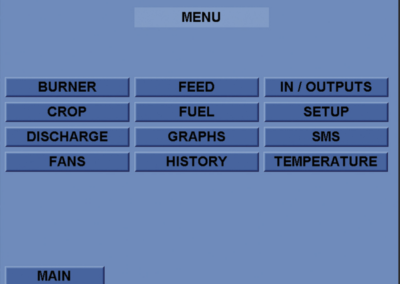

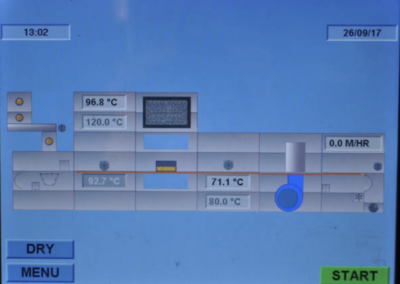

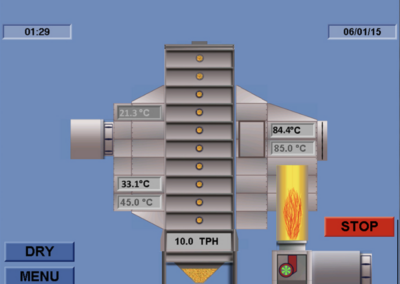

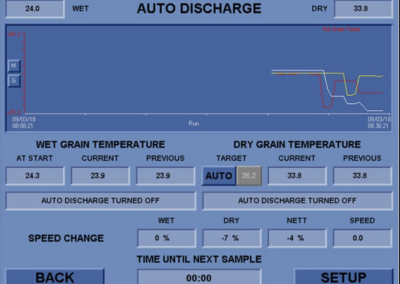

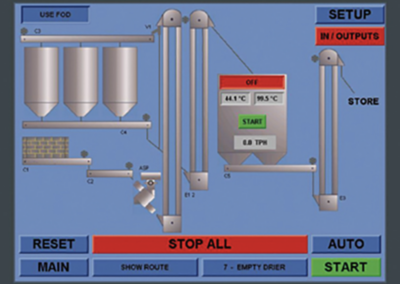

The Perry PLC Plant Control Panel is an advanced piece of technology that gives the drier operator a clear, visual representation of the machines and routes, along with offering advanced diagnostic capabilities & remote control, when the panel is connected to the internet.

You can upgrade a PLC Drier Control Panel to become a full PLC Plant Control Panel, which will allow the control panel to control an entire plant, including machines by other manufacturers.

The Perry PLC Drier Control Panel comes as standard with both the Perry Savannah Series Continuous Mix Flow Driers & the Perry Belt Drier. The difference between the two panels being the visual representation of the drier & products available in the crop set-up pages.

Key Points

- Additional cost option incorporated in drier control panels.

- Switch simply between drier and plant control view.

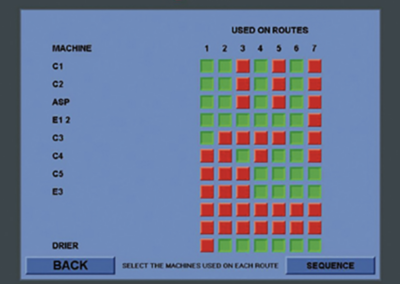

- Can control up to twenty machines as standard.

- Unique mimic drawings for each installation.

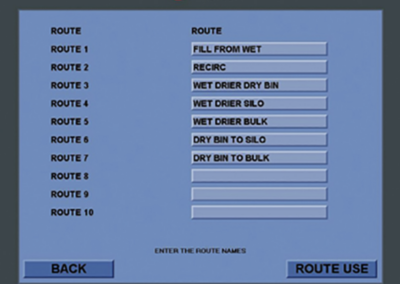

- Manual or auto route selection modes.

- Drier operation can be seen whilst in plant control panel display.

- Possible to add routes on site without reprogramming.

- Larger control panels can be provided for large installations.

Phone and Remote Application

Free app available from both Apple App Store and Google Play Store.

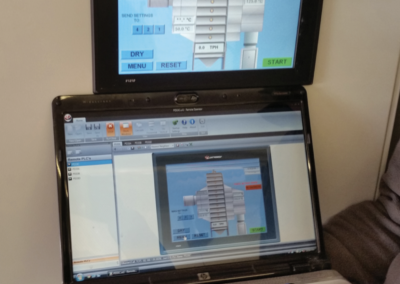

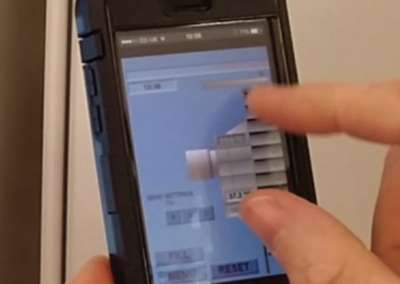

- Control a Perry drier PLC or plant panel from your phone.

- Two settings – to either view or control the panel.

- Screen shows an exact mimic of the panel.

- Full zoom compatibility making the buttons and screen easier to read.

- Static IP and passwords mean the connection is secure.

- Multiple applications can be installed on different devices.

- Multiple panels can be installed on each application.

The remote desktop allows more in-depth analysis of the control panel. Status reports and alarm history have never been so easy to access.

Sit at your computer while keeping a close eye on your grain drier & handling machinery!

Diagnostics

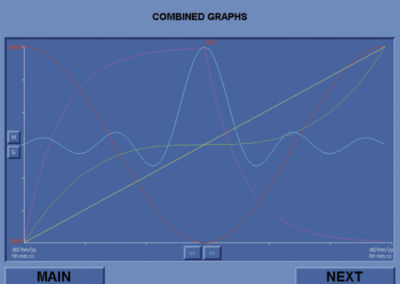

The drier history is recorded – input and output screens display current panel conditions to aid fault diagnostics. When the Perry drier is connected to the internet, diagnostics and status reports can be sent directly to a smart phone via email or text message.

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

WHY DO SO MANY IN THE FARMING COMMUNITY BUY FROM PERRY OF OAKLEY?

The machines last The Perry machines are built to last and we have our records going back well into the 1960s so if a machine needs a replacement part, we know exactly what it needs and we can get it manufactured and out to you quickly. We are so confident in the...

SEASONS GREETINGS FROM PERRY OF OAKLEY LTD.

Wishing you a fantastic festive period, and a Happy New Year, from all at Perry! Our factory will close at 5pm on Wednesday 22nd December 2021 and will reopen at 8am Tuesday 4th January 2021. If you need us urgently during the break please email...