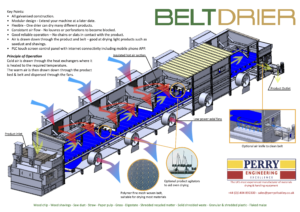

Belt Drier

The Perry Belt Drier is ideally suited to drying almost any non-flowing product or more granular products that require a lower throughput capacity. Popular applications have included woodchip, sawdust, shavings, anaerobic digestate, grass/Lucerne/hemp, SRF, RDF, seeds & many others.

Key Points

Air is drawn down through the product bed which keeps the product tight to the belt, improving drying efficiency & reducing product loss through fans via product lift.

Available in widths of 1.5m, 2.2m & 3.0m and lengths of up to 75m.

Modular construction allows the grain driers to be extended easily at a later date, allowing your drier to grow with your business.

Automatic tracking is standard to ensure the belt stays aligned without any manual input.

Slow-moving parts reduce the wear on parts meaning less maintenance.

A tightly woven, anti-static polymer belt that can withstand temperatures up to 130°C allows for very few fines to slip through the belt, meaning less product loss and less cleaning up required.

Automatic control as standard will speed up and slow down the belt to help ensure even product drying. As the hot air temperature rises below the belt it will speed the belt up automatically to help ensure you don’t over-dry your product and counter to that, it will slow the belt down as the below-the-belt temperature falls.

There are no chains, slats or louvres for the product to get caught in. This keeps the grain drier very clean and reduces damage to the material being dried.

The in-house designed and programmed PLC panel is easy to use and provides data at the touch of a button.

An Internet connection allows remote access and control of the grain drier from a smartphone or desktop PC.

Internet connectivity allows for Perry engineers to remotely diagnose any issues.

Suitable Products

We test new products on the Perry Belt Drier as and when required. We have a small testing facility at the factory that allows us to test the drying efficiencies on new products, which allows us to accurately size the grain drier for your requirements.

Suitable Products for the Perry Belt Drier include:

- Grass, straw, lucerne, seaweed, cannabis, leaves & corn fIbre

- SRF, RDF, MSW & other waste products

Paper pulp & paper mulch - Woodchip, wood shavings, sawdust & other biomass products

Digestate - Grains (including wheat, barley, maize, and many others)

Seeds - Manures & fertilisers

- Pet food

- Vegetables (including shredded & pulped).

- Stainless steel options are available.

- Brewers grains.

If you have a product you would like to dry that is not shown on this list, please contact us to arrange to send a sample of the product to the factory. If you require a bulk amount of product dried, we do have a couple of customers who contract dry and are happy for us to pass on their contact details.

Heat Sources

Perry belt driers can use LPG or natural gas (direct or indirect), Kerosene, diesel (direct or indirect), water or steam (using heat exchangers) as a heat source as standard, though existing heat sources, such as flares, can be used with some modifications to the grain drier.

Feeding and Discharge

We offer a full range of handling equipment to accompany belt driers, such as augers/screw conveyors, chain & flight conveyors, belt & bucket elevators, twin trace conveyors, belt conveyors & much more.

Along with the standard range of equipment, Perry offer a full range of feeding and discharge options specifically designed to suit belt driers, such as a multiple screw feeder option and a belt feeder option.

Optional Extras

Perry belt driers have a wide range of optional extras available to help ensure smooth running with minimal maintenance. The optional extras include:

- CentriKleens, for dust reduction from the fans.

- Hot air recirculation, to help reduce the amount of energy required to heat the drier.

- Inverter controlled fans, to help reduce the amount of energy the driers consume. This ensures complete control of air-speeds running through your product.

- Rotating agitators, to ensure the product dries evenly.

- Belt cleaning systems, including an air knife & a water jet system, to help keep the belt from becoming breached.

- Silencers, to help reduce the noise emitted by the fans.

Videos

Drying Wood Shavings

Drying Wood Fines

Drying Wood Chips

Drying SRF

Drying Grass

Drying Flaked Maize

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

WHY DO SO MANY IN THE FARMING COMMUNITY BUY FROM PERRY OF OAKLEY?

The machines last The Perry machines are built to last and we have our records going back well into the 1960s so if a machine needs a replacement part, we know exactly what it needs and we can get it manufactured and out to you quickly. We are so confident in the...

SEASONS GREETINGS FROM PERRY OF OAKLEY LTD.

Wishing you a fantastic festive period, and a Happy New Year, from all at Perry! Our factory will close at 5pm on Wednesday 22nd December 2021 and will reopen at 8am Tuesday 4th January 2021. If you need us urgently during the break please email...