Ex-Show Mobile Batch Drier

Available Immediately

£68,500+vat Ex-Works Devon, UK

This is our EX show model from 2023 and unused and as such is a very competitive price. It is available ex works Dunkeswell and comes with 12 months warranty.

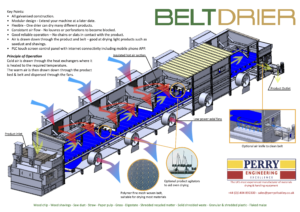

Key Points

- Agrex AGD25

- 19T Capacity

- Electric

- Cross auger for discharge to the left and right.

Complete with:

- 1.5mm stainless steel mesh

- Automatic control panel

- Centralised greasing

- Aspirator & cyclone

AGREX Case Study

The Hawthorns Estate farm is a fourth-generation family business, trading as R.N. Padfield & Sons. In 2005, Chris Padfield took over from his father, Richard, launching collaborative ventures with local farmers on cattle and arable enterprises.

The Hawthorns Estate farm is a fourth-generation family business, trading as R.N. Padfield & Sons. In 2005, Chris Padfield took over from his father, Richard, launching collaborative ventures with local farmers on cattle and arable enterprises.

The farm has changed and developed over the past 113 years to meet changing economic, social and political pressures. The estate celebrates and shares a commitment to modern, conservation-minded farming and uses methods such as direct drilling and variable rate application technologies.

The Hawthorns Estate has worked with local farmers to develop a grain storage service for those who cannot store all their own grain or who want to clean or dry grain and don’t have modern facilities. It enables those who want to take advantage of pooled marketing strategies or want space for storage of speciality crops such as beans or linseed. The Hawthorns has established partnerships for selling the stored cereals with two national grain merchants.

In 2017 when the grain drying and storage system was implemented the farm purchased their first Agrex drier, a 20T model. To keep pace with demand, after a year this was upgraded to an AGD45, a 34T model with PLC control and full automation to enable bigger batches to be dried and unattended operation.

The drier has a 1.5mm mesh so that oil seed rape and all usual combinable crops can be dried. It has a direct fired diesel burner and it is filled and emptied by 100tph handling equipment and there are 2 hopper bins for wet storage.

Chris Padfield says “ The drier has been straightforward to operate and has not needed any mechanical work to be carried out during it’s lifetime at the farm, the benefit of the automatic control is the ability to run unattended.”

“We are pleased to know that Perry and Thorburn are representing AGREX driers and have a stock of spare parts and service assistance should we need it so that gives us peace of mind during the harvest period.”

David Perry, MD of Perry Engineering says “We are very pleased to have met Chris and seen his operation and we are equally pleased to see that the drier is in very good condition after these years and to have had a good report on its operation and reliability from Chris. It confirms that the AGREX driers are not new to the UK market and work well in UK conditions”

”it’s great to be working with another drier manufacturer who makes the majority of their parts in house and are willing to tailor a product to suit the market needs. Working with Thorburn Group on this project brings years of mobile drier experience to combine with our decades of grain drying and handling experience which is so valuable and really means that all parties can hit the ground running.”

Integration with handling and storage

The AGREX mobile drier range is able to fully integrate with the Perry range of bulk materials handling and storage so all of your drying, handling and sotrage requirements can be managed by one supplier making your life easier.

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

WHY DO SO MANY IN THE FARMING COMMUNITY BUY FROM PERRY OF OAKLEY?

The machines last The Perry machines are built to last and we have our records going back well into the 1960s so if a machine needs a replacement part, we know exactly what it needs and we can get it manufactured and out to you quickly. We are so confident in the...

SEASONS GREETINGS FROM PERRY OF OAKLEY LTD.

Wishing you a fantastic festive period, and a Happy New Year, from all at Perry! Our factory will close at 5pm on Wednesday 22nd December 2021 and will reopen at 8am Tuesday 4th January 2021. If you need us urgently during the break please email...

Concept Grain Systems and Perry guided us through the processes of updating our machinery; the level of expertise within the company has helped us no end. The Perry machines they recommended we installed have worked really well, and as a result, we had a very successful first year.