Agricultural Belt and Bucket Elevator

Perry of Oakley Ltd. have a wide range of belt & bucket elevators available, whether you are looking for seed elevators, budget elevators, high capacity elevators there is an elevator to suit every customers’ needs.

As standard, Perry elevators are capable of handling grains, peas, beans, woodchip, sawdust & many other free-flowing materials. With some minor modifications, they can be made suitable for seeds and other products that require more delicate handling, along with products that are more abrasive & hazardous to handle.

Capacities of the agricultural belt & bucket elevators range from 11tph to 150tph. Elevator models are available in both single and double lift, and each one can be easily converted to be made suitable for seed handling. All elevators are manufactured in durable galvanised steel to increase life span, and each elevator model has a wide range of optional extras available, ensuring each Perry elevator is manufactured suited to individual requirements.

As standard Perry elevators are fitted with slatted pulleys – reducing the build-up of material on the pulleys. A low stretch rubber, oil-resistant EP belt is used, with Nitrile belts available at a small extra cost. Vee belt drives to shaft mounted gearboxes are offered as standard, with an option of 90° gear unit drives also available. Gearboxes arrive prefilled with lubricant to enable a quick and easy installation.

Model 220 & 440 Elevators

This elevator is specifically designed to a high specification single and double lift elevator at a very competitive price.

- Capacities up to 80tph.

- The entire head shaft assembly is removable with gearbox and bearing attached without disassembly—a major advantage when maintaining old elevators.

- Head and boot shell 3mm thick.

- Heavy-duty welded construction hot-dip galvanised head cap.

- Range of speeds to provide centrifugal, slow centrifugal and gravity discharge.

- Master cup belt tensioner mounted on the cup belt for easy joining & tensioning.

- Can be made suitable for seed handling.

- Maximum standard height of 30m.

Model 200, 280 & 560 Elevators

This elevator is specifically designed with a very low boot inlet height and short head. It is ideally suited to being used in old installations and where space is tight.

- Single & double lift versions available.

- It also has a slower belt speed making it kinder to some products.

- Can be made suitable for seed handling.

Model 330 Elevator

This elevator is specifically designed to a high specification for heavy-duty use.

- Single lift belt & bucket elevator.

- High capacity of up to 150tph.

- Heavy-duty construction.

- Belt tension via adjustable boot pulley.

- 5mm thick head cap.

- Can be made suitable for seed handling.

Option Extras

A wide range of optional extras are available for our bucket elevators, ensuring all individual requirements are met.

- All elevators are available with an access platform and ladders and hoops meeting all safety standards.

- All elevators can be designed and manufactured to meet ATEX requirements.

- A wide variety of inlet options helps ensure smooth transitions between machines.

- Rotation & under-speed sensors, help ensure your elevator runs smoothly.

- All elevators have options available to make them suitable for seed handling.

- Various drive handing and mounting options to help reduce the amount of space required.

Industrial Belt and Bucket Elevators

Capacities of industrial belt & bucket elevators range from 100tph to 1000tph and are suitable for full commercial use. Elevators are available in both single and double lift, and each one can be easily converted to be made suitable for seed handling.

All Perry elevators are manufactured in durable galvanised steel to increase life span, and each elevator model has a wide range of optional extras available. Vee belt drives to shaft mounted gearboxes are supplied as standard, with an option of 90 degree gear unit drives also available. Gearboxes arrive prefilled with lubricant to enable a quick and easy installation.

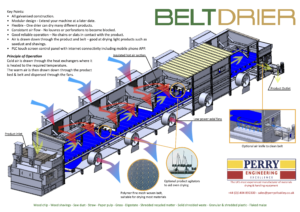

Everything You Should Know About Grain Sentry Fire Detection

When correctly positioned and functioning, the Perry Fire Detection System can help provide early warning of a fire, helping to reduce potential damage to your drier. It’s used for detecting fire within a grain drier drying column. Belt Drier Fire Detection...

Which Type of Grain Drier Should I Buy?

With over 70 years of experience, Perry Engineering are the UK’s most experienced manufacturer of materials drying and handling equipment. Our driers are relied on to dry a variety of crops in different climates all over the world. How do you know which type of grain...

Why Buy a Perry Mistral Grain Drier?

Investing in the Mistral Grain Drier Grain drying is a Perry of Oakley speciality, and our extensive expertise has established us as a leader in this field. At Perry we’re world-renowned for manufacturing continuous-flow grain driers. We’ve been successfully...