Belt Conveyors

Perry’s range of belt conveyors are suited to both agricultural and industrial applications and are available in widths up to 2m. They are manufactured using high quality, durable galvanised steel and have a three piece steel trough construction or a three roller trough belt assembly. These conveyors are ideal for filling large storage sheds, and handling products that have poor flowability.

Key Points

- There are many inclined applications up to 30 degrees depending on the product being handled.

- Exceptionally rigid construction, easily capable of spanning 6m building bays.

- Section joints are of dimpled style, guaranteeing accurate alignment, and a smooth and strong connection.

- Where a tripper device is specified, it can be either motorised or hand operated. It is of a winched design; there is no electrical power supply to the tripper requiring an expensive catenary cable.

- Two manually adjusted tensioning screws are fitted to the tail end.

- Belt take up unit fitted on lengths over 50m.

- Gravity tensioner unit also available.

- Standard belt type is PVG compound type, with a polyester carcass, giving excellent oil, mildew resistance, flame retardance to ISO. 340 and a satin top cover finish for improved product release.

- A wide range of other belt specifications are available including grip face or chevron for use on inclined applications or other belt compounds for use when handling specific products.

Included as Standard

- All galvanised construction.

- Troughs supplied in standard lengths of 2.4m, 1.8m, 1.5m, 0.9m and 0.6m, preassembled.

- Drive and tail section factory assembled.

- Manually adjusted cleaning brush at drive end.

- All motors and gearboxes are factory fitted.

- PVG compound belt with good oil, mildew and rot resistance with factory fitted lace and joiner.

Optional Extras

- Inlet hopper.

- Weather proofing.

- Manual / motorised tripper.

- Drive end tensioner.

- Rotary brush.

- APEX belting and other specialist belting is available.

Belt Conveyor Tripper

Belt Conveyor tripper

Belt Conveyor Tripper Control

Everything You Should Know About Grain Sentry Fire Detection

When correctly positioned and functioning, the Perry Fire Detection System can help provide early warning of a fire, helping to reduce potential damage to your drier. It’s used for detecting fire within a grain drier drying column. Belt Drier Fire Detection...

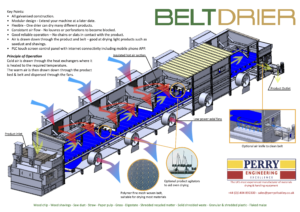

Which Type of Grain Drier Should I Buy?

With over 70 years of experience, Perry Engineering are the UK’s most experienced manufacturer of materials drying and handling equipment. Our driers are relied on to dry a variety of crops in different climates all over the world. How do you know which type of grain...

Why Buy a Perry Mistral Grain Drier?

Investing in the Mistral Grain Drier Grain drying is a Perry of Oakley speciality, and our extensive expertise has established us as a leader in this field. At Perry we’re world-renowned for manufacturing continuous-flow grain driers. We’ve been successfully...