Aspirator Pre-Cleaners

The Perry In-line Aspirator Pre-Cleaner removes dust, chaff, husks, awns and material lighter than the grain to help improve the quality of a product before it is dried. Three capacities are available: 30tph, 60tph (to achieve 120tph two 60tph models can be used in tandem) and 150tph.

Grain is internally spread over the full width of the chamber and the air is pulled through the cascading grain to remove the light dust and chaff. The rate of airflow can be adjusted to suit a variety of crops with an adjustable slide using the chain wheel at the side of the cleaner. Perry also manufacture a full range of exhaust ducting and cyclones to collect the rubbish removed.

Key Points

- Capacities up to 150tph.

- Ideal for removal of light dust & chaff and excellent at improving the bulk density of light crop samples.

- Fan can be situated on cyclone so the exhaust ducting is under negative pressure to minimise dust leaks.

- Comes complete with four fitted mounting brackets.

- All galvanised construction for outdoor use.

- Three separately adjustable cleaning sections.

- Triple extraction point for three times the performance.

- 500mm diameter clip together exhaust ducting.

- Fully adjustable internal guides to ensure the best performance on every crop.

- Side viewing panels to see the effect of adjustments.

- Air control by variable speed drive.

Everything You Should Know About Grain Sentry Fire Detection

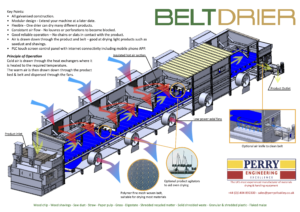

When correctly positioned and functioning, the Perry Fire Detection System can help provide early warning of a fire, helping to reduce potential damage to your drier. It’s used for detecting fire within a grain drier drying column. Belt Drier Fire Detection...

Which Type of Grain Drier Should I Buy?

With over 70 years of experience, Perry Engineering are the UK’s most experienced manufacturer of materials drying and handling equipment. Our driers are relied on to dry a variety of crops in different climates all over the world. How do you know which type of grain...

Why Buy a Perry Mistral Grain Drier?

Investing in the Mistral Grain Drier Grain drying is a Perry of Oakley speciality, and our extensive expertise has established us as a leader in this field. At Perry we’re world-renowned for manufacturing continuous-flow grain driers. We’ve been successfully...