Air Screen Cleaners

Together with Westrup, Perry Africa offers a comprehensive range of air screen cleaning equipment for pre-cleaning, fine cleaning and grading for different types of crops.

The air screen cleaners and graders can be designed specially to your needs ensuring the stability of your seed cleaning process.

Our range of air screen cleaners and graders consists of basic machines and modular solutions.

Basic Machines

A basic machine can easily be part of a complex cleaning operation. Whether to choose a basic machine depends on your crop, your requirements and your processing needs.

Modular Solutions

Westrup’s modular system offers you a choice of more than 60 different modules. When choosing a modular solution, we design the best cleaner or grader for your specific requirements.

We select the exact combination of feeding, pre- and final aspiration andsieve modules that will make up the solution that suits your business goal.

Navigator 4.0

Our automation system, Navigator 4.0, enables you to achieve process stability. With easy access to machine settings, preset recipes and intelligent alarms you have full control of your air screen pre and fine cleaners.

Adding the Adaptive Aspiration Control will allow you to maintain a constant air flow in the prodcut sorting zones, decreasing the amount of good product found the in waste.

Air Screen Pre-Cleaners

REMOVAL OF LARGE IMPURITIES

Air screen pre-cleaners are used to remove large impurities from incoming seed and grain to relieve the following machines and ready the product for storage.

Westrup offers a comprehensive range of air screen pre-cleaning equipment for different purposes, among these for cleaning, sizing, precleaning, market grade cleaning and food grade cleaning. Capacities range from low capacity machines suitable for grain storage facilities to high capacity machines suitable for high intake plants.

CAPACITIES: from 12-380 t/h based on wheat

Air Screen Fine Cleaners

REMOVAL OF LIGHT IMPURITIES

Air screen fine cleaners remove light impurities by using a precise air stream to lift light foreign material away from the prime product and sieveboats with scalping and sand screens to remove small and large impurities.

Westrup offers many versatile air screen fine cleaning machines suitable for many purposes, amongst these precision cleaning, fine cleaning and sizing.

CAPACITIES: from 1.7-48 t/h based on wheat

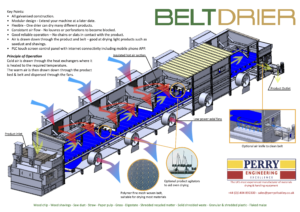

Everything You Should Know About Grain Sentry Fire Detection

When correctly positioned and functioning, the Perry Fire Detection System can help provide early warning of a fire, helping to reduce potential damage to your drier. It’s used for detecting fire within a grain drier drying column. Belt Drier Fire Detection...

Which Type of Grain Drier Should I Buy?

With over 70 years of experience, Perry Engineering are the UK’s most experienced manufacturer of materials drying and handling equipment. Our driers are relied on to dry a variety of crops in different climates all over the world. How do you know which type of grain...

Why Buy a Perry Mistral Grain Drier?

Investing in the Mistral Grain Drier Grain drying is a Perry of Oakley speciality, and our extensive expertise has established us as a leader in this field. At Perry we’re world-renowned for manufacturing continuous-flow grain driers. We’ve been successfully...