Advanced Grain Cleaning

Together with Westrup, Perry of Oakley offers a comprehensive range of advanced grain cleaning equipment for different types of crops.

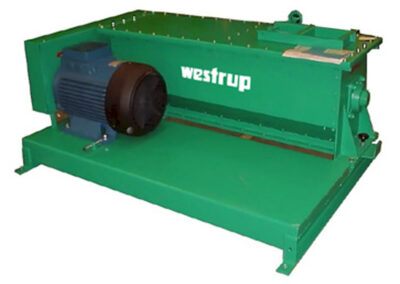

De-Awners

REMOVAL OF AWNS, HUSKS AND CLIPPING OF SEED

De-awners are used for pre-treatment of various grain types; the purpose of the de-awning operation is to remove awns from barley kernels, loose husks from wheat and to clip oat kernels.

The de-awner can be used where heavy de-awning is required but also for products where only a light de-awning is needed. The degree of de-awning depends on the amount of time the product takes to pass through the housing of the machine.

CAPACITIES: from 6-25 t/h based on wheat

Brushing Machines

POLISHING AND SPLITTING SEED

Brushing machines are very useful in grass seed installations, especially for splitting twin kernels.

The machines are very easy to clean and therefore very suitable for basic seed plants and installations for the production of flower and garden seed.

The rotating shaft can be installed with different types of brushes or steel beaters to ensure a highly efficient treatment of a wide range of products.

CAPACITIES: from 0.5-1.5 t/h based on grass seed

Drum Cleaners

REMOVAL OF COARSE IMPURITIES

The drum cleaner (DC) and drum pre-cleaner (DP) are used to remove coarse impurities, such as paper, pieces of wood or corn cobs from the main product.

Both drum cleaners are suitable for intake sections and silos to relieve the following machines and conveyors.

CAPACITIES: from 100-200 t/h based on wheat

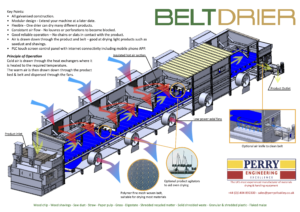

Fluid Bed Driers

A DRIER AFTER TREATMENT

Our fluid bed drier is designed as a surface drier to use after a chemical treatment process and can be used for most kinds of treated seeds.

The inlet section is built to ensure an even spread of product over the full working width of the machine.

For very fragile seeds, it is recommended to fit the FBD with variable speed to protect the seeds from being damaged during processing.

CAPACITIES: from 6-15 t/h based on corn

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

WHY DO SO MANY IN THE FARMING COMMUNITY BUY FROM PERRY OF OAKLEY?

The machines last The Perry machines are built to last and we have our records going back well into the 1960s so if a machine needs a replacement part, we know exactly what it needs and we can get it manufactured and out to you quickly. We are so confident in the...

SEASONS GREETINGS FROM PERRY OF OAKLEY LTD.

Wishing you a fantastic festive period, and a Happy New Year, from all at Perry! Our factory will close at 5pm on Wednesday 22nd December 2021 and will reopen at 8am Tuesday 4th January 2021. If you need us urgently during the break please email...