The Grain Sentry

Automatic Grain Moisture Monitoring System

Reduce Your Drier Operating Costs

Grain Sentry is Perry of Oakley’s Automatic Drier Moisture Monitoring System which controls the drier temperature and discharge speed automatically by measuring the input and output grain moisture content.

How does it work?

The system uses pneumatic conveying to take a grain sample from the drier filling and discharge equipment.

This sample is analysed using the very latest Near Infrared technology to ascertain the moisture content, which provides industry standard accuracy for the moisture measurement for every sample.

Our software, written by Perry engineers, uses the information in a series of calculations to determine the correct change needed to the drier speed to maintain the best possible output grain moisture content.

How does it save me money?

The combination of the accurate moisture meter and the self- teaching algorithm system prevents the quite large financial losses associated with over-drying grain such as decrease in weight, extra fuel usage, labour, and electricity, for example. This means big savings and peace of mind can be achieved, especially when coupled with the manpower savings from using a moisture meter that only requires annual calibration.

How big are the savings?

Based on a 30tph throughput drier, drying 6000T per season in average conditions the direct drying cost savings would be £21,500 per season. Contact us with your real-life data and we’ll run it through our calculator and show you how much you could save.

What products does it work on?

Products that can be measured as standard include: wheat, barley, oats, triticale, rye, corn, buckwheat, millet, sorghum, rice, coffee, peas, lupin, soybean, rape, sunflower, jojoba, seaweed.

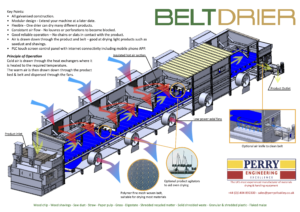

What drier can it be used on?

It can be retro-fitted on to any shutter discharge continuous flow grain drier, and is a recommended optional extra on all Perry Savannah Series driers.

Key Points

- The system is not affected by build up on the sensors.

- The sampled product is returned pneumatically to any suitable point.

- Sample intervals can be tailored but the minimum is approximately 2 minutes.

- The system controls both drying temperature and speed

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

WHY DO SO MANY IN THE FARMING COMMUNITY BUY FROM PERRY OF OAKLEY?

The machines last The Perry machines are built to last and we have our records going back well into the 1960s so if a machine needs a replacement part, we know exactly what it needs and we can get it manufactured and out to you quickly. We are so confident in the...

SEASONS GREETINGS FROM PERRY OF OAKLEY LTD.

Wishing you a fantastic festive period, and a Happy New Year, from all at Perry! Our factory will close at 5pm on Wednesday 22nd December 2021 and will reopen at 8am Tuesday 4th January 2021. If you need us urgently during the break please email...