Bio-Intake

The Perry BioIntake combines a reception hopper with a vertical auger to seamlessly move the biomass fuel from the point of delivery by a standard tipper truck into the biomass storage area, at the push of a button. The hopper comes fitted with an easy to operate winched lid, which when open acts as a splash back to minimise the spill of the fuel during the tipper truck delivery. Any blockages during the delivery can be easily remedied as the construction of the BioIntake is tubular, allowing for the removal of side panels. It has been designed to require two hand operation of the safety switch to ensure the operator is in the view of the tipping pit at all times. The BioIntake has been designed to operate at less than 60db, making it one of the quietest Biomass delivery systems available on the market. The BioIntake is ideally suited to larger commercial properties using approximately 500m³ of woodchip a year.

Key Points

- Only requires a flat concrete pad for installation saving the cost of complicated concrete work.

- Above ground intake system for the delivery of woodchip by trucks and trailers.

- All galvanised construction for a long outside life.

- Suitable G30 and G50 W30 woodchip.

- Capacity of 60m³ per hour in G50 forestry woodchips.

- Winched lid and control switch lid can be padlocked shut to prevent unauthorised use or vandalism.

Images

Everything You Should Know About Grain Sentry Fire Detection

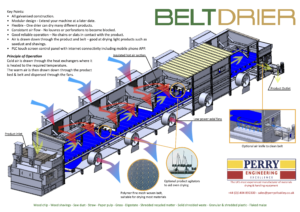

When correctly positioned and functioning, the Perry Fire Detection System can help provide early warning of a fire, helping to reduce potential damage to your drier. It’s used for detecting fire within a grain drier drying column. Belt Drier Fire Detection...

Which Type of Grain Drier Should I Buy?

With over 70 years of experience, Perry Engineering are the UK’s most experienced manufacturer of materials drying and handling equipment. Our driers are relied on to dry a variety of crops in different climates all over the world. How do you know which type of grain...

Why Buy a Perry Mistral Grain Drier?

Investing in the Mistral Grain Drier Grain drying is a Perry of Oakley speciality, and our extensive expertise has established us as a leader in this field. At Perry we’re world-renowned for manufacturing continuous-flow grain driers. We’ve been successfully...

The AC150 has worked out to have many uses to us. It was initially put in to improve low bushel weight milling wheat, but since installation we have found that it will clean beans to near seed quality, it will improve bushel weight on all cereals and will also clean out bugs without the need for sprays and as an added bonus there’s no screens to change so no changeover time need between crops. We are very happy with the system and would recommend it.