Strawson’s go back to trusted supplier

18TH October 2019

In 1998, Strawson’s Farms, Louth, installed a range of 30tph & 60tph grain handling equipment from Perry and a 20tph drier. More recently, Mr Strawson had found this system has not been able to keep up with the amount of grain he is now producing on the farm, and so made the decision to upgrade the drier and handling equipment. Each year, Mr Strawson intends to dry up to 6,000 tonnes, which will be a mixture of wheat, barley, oilseed rape and beans.

It was decided the 20tph drier would be upgraded to a Perry 50tph M611 drier and to upgrade the handling equipment to the 100tph Perry heavy duty agricultural range of conveyors and elevators along with re-using one of the older Perry conveyors.

The heavy duty agricultural range (from 60tph to 120tph) is a mid-range specification that bridges the gap between the lower capacity agricultural range (from 8tph to 60tph) and the high capacity industrial range of products (from 60tph up to 800tph). All of this range of Perry conveyors are designed and manufactured in house and has an all bolted and rivetted construction with heavy duty dimple form countersunk joint for high mechanical strength. The heavy duty agricultural range is suitable for throughputs of up to 30,000 tonnes per annum.

The new handling equipment at Strawson’s Farms incorporates a 100tph curved combination conveyor, two 100tph store filling conveyors, a 100tph flow and return conveyors & two 100tph single lift elevators. Mr Strawson was happy to use Perry handling equipment as it had performed well on the original installation and found it straightforward to use and easy to maintain.

Mr Strawson’s new M611 drier is fitted with Perry’s new Light Grain & Chaff Recovery System (LGCRS), which is a pneumatically operated system that is installed at the base of the exhaust plenum. It has been designed to help reduce the build-up of dust, chaff and seeds in the plenum by periodically discharging any product that may have been pulled from the grain column and puts it back with the main grain flow.

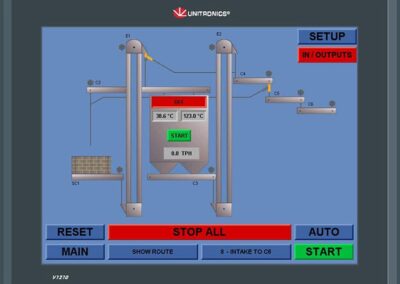

The whole system is controlled using the Perry’s PLC drier and plant control panel. The touchscreen PLC panel has been designed and programmed by Perry engineers and is capable of controlling up to ten machines as standard along with the drier. The panel displays a mimic of the complete store as well as having multiple automatic routes available.