Flaking Mill Upgrade

17th October 2019

Perry are the UK’s most experienced manufacturer of materials drying & handling equipment. Established in 1947, 2017 marked 70 years of successful installations of British manufactured machines. Perry export machines globally and are well represented with a network of dealers & specialist engineers worldwide.

Perry are best known for grain handling and drying equipment, and are well established within the agricultural industry. Solutions are provided for many other industries including coal, minerals, biomass (including wood chip, sawdust, shavings & pellets), sewerage & sludge, digestate, rubbish/refuse, grass & many others. The launch of the Perry Belt Drier also provides other industries with fast, efficient and cost effective drying solutions.

In 2015, Perry provided a company with a drying and handling solution for a commercial feed plant that produces flaked maize for dairy cow feed. The installation was completed over several stages in order not to disrupt the production of the flake.

The company needed to increase output from approximately 5tph of dried and cooled and 9tph undried flake to 25tph of dried and cooled flake. There were two existing lines, LINE 1 – a full flaking, drying and cooling line and the other, LINE 2 – a flaking line only, the undried flake had a poor storage life and didn’t allow the company to produce a stock pile. With no stock pile, when the flaking line malfunctioned feed stock became low.

Stage one of the upgrade involved increasing input to the tempering bins in order to keep the planned and existing flaking lines fed with sufficient raw material. A new line between the dry bin and the tempering bins was added. From the dry bin a 10tph chain & flight store conveyor takes the corn through an aspiration unit, cleaning away any light impurities. An auger then feeds a 12.5m belt & bucket elevator, which in turn feeds a milling separating machine, another aspiration unit and then a destoner.

Perry’s range of belt & bucket elevators are capable of capacities of up to 1000tph. As standard, Perry’s belt & bucket elevators are manufactured from heavy duty, durable, galvanised steel. Perry manufacture three standard ranges of bucket elevators suitable for agricultural, commercial & industrial use. With a wide range of optional extras available, each one is carefully designed to suit each customers’ requirement, ensuring that every machine manufactured is fit for purpose.

After the destoning process the kernels are taken via another belt & bucket elevator, through to a highly sophisticated dampening system to take the moisture content from around 11% to 18%, ensuring the corn is ready for tempering. The dampening system comes with automatic moisture control & water dosage. It is a stainless steel measuring channel with online temperature, moisture & hectolitre weight measurements.

A series of belt & bucket elevators and chain & flight conveyors then transports the dampened corn to tempering bins. The tempering process then takes between 8 and 12 hours.

Perry supplied and installed most of the equipment within the new pre-dampening line, including sourcing and installing the specialist machinery. They were able to adapt the existing machinery to suit the new system currently installed, helping to keep costs to the customer to a minimum.

Stage two of this installation was to install a third flaking line (LINE 3). The new flaking line takes the tempered kernels via a pre-existing belt & bucket elevator through a bullet type magnet, which removes any metallic impurities ensuring the pin rollers within the flaking mill are not damaged. An existing conveyor then feeds a new store conveyor that is connected to a surge bin. The store conveyor is equipped with electro-pneumatic outlets, which allows the surge bins to call for the kernels when they are needed. The surge bins then feed a steam chest, which cooks the kernels and feeds them into the flaking mill.

Perry’s range of store conveyors are capable of handling capacities of up to 1000tph and are all manufactured using highly durable galvanised steel. They come in widths from 7” right up to 1m wide. There is no metal to metal contact on any of the chain and flight conveyors, helping to increase the longevity of the conveyors. A range of chain speeds are offered to suit various different products, ensuring minimal damage to the product while being conveyed.

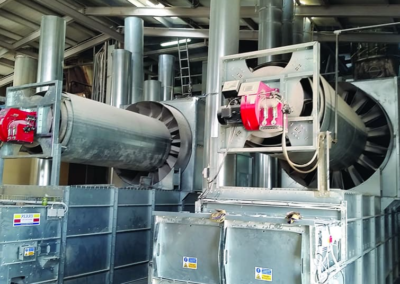

Once the corn has been flaked, the flakes are then discharged directly into a Perry Belt Drier, which takes the moisture content of the flakes from 23% down to 11% by drying and cooling the flakes, which gives the flakes a much longer storage life. The customer installed a 10tph belt drier, but currently only requires it to output approximately 8tph.

The Perry belt drier has proven to be an effective tool for drying flaked maize as, unlike other driers, air is drawn down through the product bed, meaning there is minimal product lift. There are also no slats or chains to come into contact with the product, meaning there is minimal product damage during the drying and cooling process. The consistent air flow within the belt drier is aided by the fact that there are no louvres or perforations to become blocked, this also means that in this particular application the Perry belt drier requires less frequent cleaning than that of competitors.

On discharging from the drier, the dry flakes are deposited into a new chain & flight conveyor that feeds directly on to an existing belt conveyor, which in turn takes the dried flake in to stores.

Perry’s experienced engineers were able to supply and install the full flaking line, including the surge bin, steam chest and flaking mill along with adapting the existing machinery to ensure the whole process runs efficiently and smoothly.

With the new flaking line installed and working efficiently, the third stage of this installation involved shutting down LINE 2 in order to add a belt drier to dry and cool the flakes after the flaking process. The Perry Belt drier installed in LINE 3 had proven to be a lot more efficient and required a lot less maintenance than the existing drier in LINE 1 so the customer opted to install another 10tph Perry Belt Drier.

The second Belt Drier discharges in the same manner as the first, including feeding the same belt conveyor that takes the dried flake to stores.

By improving the pre-tempering line, adding a whole new line and improving the second line Perry have now increased the customers overall output to an average of 25tph. This has allowed the customer to meet ever increasing demand and allows for further growth. They also now have a stock pile of flaked maize, which reduces the pressure on all three lines, allowing them to work under their maximum output.

Perry can provide handling equipment with capacities from 8tph up to 1000tph suitable for full commercial use. Industrial specification handling available includes chain & flight conveyors (horizontal, inclined & curved combinations), mechanical reception pits, belt & bucket elevators, belt conveyors, twin trace conveyors & augers / screw conveyors. All machines are manufactured to the highest standard using the latest engineering and manufacturing technologies.

If you require a solution similar to the one described in this article, or another drying or handling solution please contact Perry on +44 (0)1404 890300 or email [email protected]