Bio Mass Fuelled Grain Drier

17th October 2019

For harvest 2013 Balbirnie Estate, located near Glenrothes in Scotland, installed an all biomass fired Perry continuous flow grain drier.

The existing oil fired drier had a shutter, or bomb, door discharge mechanism, which is considered to work especially well in Scotland due to the wetter harvesting conditions. Since this was installed the amount of grain requiring drying has increased from 1,500 tonnes to 6,000 tonnes.

As a replacement for the existing drier Balbirnie’s owner, Robert Balfour, and the estate manager, David Algen, decided to install a continuous mixed flow drier with the same type of shutter discharge that was capable of drying in a day what is typically harvested in a day, which equated to 300 tonnes per day. K M Duncan were appointed to install the drier and handling equipment, manufactured and supplied by Perry.

Due to the large amount of timber within the estate, Balbirnie wanted to use their own woodchip as a heat source for drying their grain.

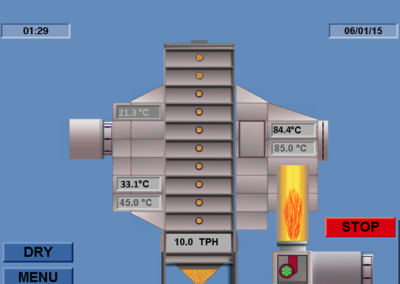

The drier selected was a Perry model M612 drier, which is capable of achieving up to 50tph throughput when running at 125 degrees Celsius and drying to 14% moisture content. Perry worked directly with the biomass boiler supplier to ensure that their interface and burner were fully compatible with the Perry drier & control panel. The PLC drier panel fully controls the biomass boiler and the normal functions of the grain drier. The panel provides data logging of all the drier performance and has the ability to be remote connected to by Perry staff at their factory in Devon using an internet connection, meaning the drier performance can be monitored and adjusted if necessary. One feature that David Algen has made particular use of is the automatic mode on the drier control – he has been able to leave the drier unattended when operating.

In order for the drier to be compatible with a biomass heat source, extra considerations had to be made. Firstly, due to the design of the burner, the heat transfer uses an air to air heat exchanger so the drier is indirect fired. The heat source generates 2MW of heat which can provide a maximum hot air temperature of 100 degrees Celsius, so the drier is not running at its full capacity. Because the majority of the crop to be dried is malting barley and seed oats with a drying temperature of 65-70 degrees Celsius, this is more than adequate.

Secondly, if the drier shuts down, the heat source cannot be shut off immediately as it can be in a standard drier, so the drier has two hot air bypass valves incorporated into the design so the additional heat can be vented from the drier if necessary. Also, to lower the height of the drier to help fit into the building, Perry incorporated an integral discharge conveyor into the drier. To minimise heat loss the furnace and hot air plenum of the drier was supplied insulated by Perry.

The intake pit is created from two 60tph curved mechanical intake conveyors, each fitted with inverters. The grain is passed through an AC60 aspirator cleaner before a rotary screen cleaner in front of the drier. It is also passed through an AC60 Aspirator cleaner after the drier to further improve the grain sample. The storage shed is filled by two belt conveyors with moveable trippers.

The woodchip is taken from a bunker by an inclined screw conveyor and into a slow running belt & bucket elevator, which then feeds the two woodchip burners. The specification of the equipment was heavy duty agricultural / light industrial.

Balbirnie plan to have their timber chipped once a year into 30/G50 woodchip, after drying the timber for 12 to 18 months, then storing the chip in an adjacent building. They predict a saving of £50,000 each year on fuel costs alone, and after running this year’s harvest through the new system they have had no issues to report.

For further information e mail [email protected] or call 01404 890300.